- Posts: 186

- Thank you received: 70

×

Tips and techniques for getting the most out of surfskiing.

Venturi-ectomy – Bailer-plasty

- Simon Haywood

-

Topic Author

Topic Author

- Offline

- Elite Member

Less

More

10 years 6 months ago #21995

by Simon Haywood

Previous craft: Affinity, Endorfinn, Multisport, Epic V8, V10sport, V10, V12, Fenn Swordfish, Spirit PRS Elite; Stellar S18S, SR, SE, SEL, S2E, S2EL

Current Skis:

Huki S1-R

Stellar S18S - Excel

Stellar SR - Ultra

Skis on order: None!

Venturi-ectomy – Bailer-plasty was created by Simon Haywood

In response to several requests, this is how I’ve fitted Andersen Super Mini (‘Special’) bailer to a Stellar SEI (excel)...There are some short cuts I've found along the way (*SC = short cuts).

Like any operation there are several ways of performing it - this is just one...

Part 1.

Operation: ‘Venturi-ectomy – Bailer-plasty’ Nov 13’

NB: This will probably affect my warranty on my ski – but I’d rather have better drainage.

Disclosure: I’m a ‘C’ grade paddler (and not a good one at that!), I have no formal qualifications in boat building – But, I do have close access to one for advice & help...and nearly 40 years experience mucking around with boats.

First of all – Make a mould – This will pay dividends in time/finish. The mould is just two blocks of timber which is glued & screwed together then covered in flowcoat/gelcoat. When finished - Use wax & release agent...Apply the finish gelcoat to the mould – Then apply three layers of 200grm Carbon Fibre & a little bit of chop strand mat – I use West 105 epoxy resin.

Remove the bottom rail (this is screwed and glued in - *SC: do not remove - use a dremel tool to cut & shape) Remove hood & bullet off the bottom – I used a chisel – (*SC: grind it off)

Using the mould/tray you made as your template mark out where it sits and cut out – inside & out.

Fit the bailer to newly created tray – countersunk bolts are fitted from the underside-out – these need to be notched and glassed in (so they do not spin).

You must bond the inside(deck) to hull be sure to fill all the exposed nomex cells – this needs to air/water tight – I use mix of resin, micro balloons/q cells with glass strands mixed in. Use the same process to bond/glass the tray too.

Fill fair and gelcoat the interior / Spray gelcoat to the exterior

Like any operation there are several ways of performing it - this is just one...

Part 1.

Operation: ‘Venturi-ectomy – Bailer-plasty’ Nov 13’

NB: This will probably affect my warranty on my ski – but I’d rather have better drainage.

Disclosure: I’m a ‘C’ grade paddler (and not a good one at that!), I have no formal qualifications in boat building – But, I do have close access to one for advice & help...and nearly 40 years experience mucking around with boats.

First of all – Make a mould – This will pay dividends in time/finish. The mould is just two blocks of timber which is glued & screwed together then covered in flowcoat/gelcoat. When finished - Use wax & release agent...Apply the finish gelcoat to the mould – Then apply three layers of 200grm Carbon Fibre & a little bit of chop strand mat – I use West 105 epoxy resin.

Remove the bottom rail (this is screwed and glued in - *SC: do not remove - use a dremel tool to cut & shape) Remove hood & bullet off the bottom – I used a chisel – (*SC: grind it off)

Using the mould/tray you made as your template mark out where it sits and cut out – inside & out.

Fit the bailer to newly created tray – countersunk bolts are fitted from the underside-out – these need to be notched and glassed in (so they do not spin).

You must bond the inside(deck) to hull be sure to fill all the exposed nomex cells – this needs to air/water tight – I use mix of resin, micro balloons/q cells with glass strands mixed in. Use the same process to bond/glass the tray too.

Fill fair and gelcoat the interior / Spray gelcoat to the exterior

Previous craft: Affinity, Endorfinn, Multisport, Epic V8, V10sport, V10, V12, Fenn Swordfish, Spirit PRS Elite; Stellar S18S, SR, SE, SEL, S2E, S2EL

Current Skis:

Huki S1-R

Stellar S18S - Excel

Stellar SR - Ultra

Skis on order: None!

Please Log in or Create an account to join the conversation.

- Simon Haywood

-

Topic Author

Topic Author

- Offline

- Elite Member

Less

More

- Posts: 186

- Thank you received: 70

10 years 6 months ago - 10 years 6 months ago #21996

by Simon Haywood

Previous craft: Affinity, Endorfinn, Multisport, Epic V8, V10sport, V10, V12, Fenn Swordfish, Spirit PRS Elite; Stellar S18S, SR, SE, SEL, S2E, S2EL

Current Skis:

Huki S1-R

Stellar S18S - Excel

Stellar SR - Ultra

Skis on order: None!

Replied by Simon Haywood on topic Venturi-ectomy – Bailer-plasty

Part 2.

Sand & polish interior & exterior

Fit the Andersen Bailer with sikaflex 241 – job done!

I did this a year ago – no leaks to the inside of hull – no structural failures either.

Note:

1. All bailers weep to some extent – so it will not eliminate water coming into the cockpit. But you can open & shut at will and drain as required.

2. Doing this by unauthorised repairer will probably void some part of your warranty - if not all.

3. There are people who do this for a living (I don’t)– so if you’re unsure get them to do it for you...It’s about 4-5 hours work spread over about two weeks allowing for drying/curing.

Sand & polish interior & exterior

Fit the Andersen Bailer with sikaflex 241 – job done!

I did this a year ago – no leaks to the inside of hull – no structural failures either.

Note:

1. All bailers weep to some extent – so it will not eliminate water coming into the cockpit. But you can open & shut at will and drain as required.

2. Doing this by unauthorised repairer will probably void some part of your warranty - if not all.

3. There are people who do this for a living (I don’t)– so if you’re unsure get them to do it for you...It’s about 4-5 hours work spread over about two weeks allowing for drying/curing.

Previous craft: Affinity, Endorfinn, Multisport, Epic V8, V10sport, V10, V12, Fenn Swordfish, Spirit PRS Elite; Stellar S18S, SR, SE, SEL, S2E, S2EL

Current Skis:

Huki S1-R

Stellar S18S - Excel

Stellar SR - Ultra

Skis on order: None!

Last edit: 10 years 6 months ago by Simon Haywood. Reason: additional info

Please Log in or Create an account to join the conversation.

10 years 6 months ago #22013

by JonathanC

Replied by JonathanC on topic Venturi-ectomy – Bailer-plasty

Thanks for the great 'how to' Simon.

Did you put a layer of glass lapping over the inside face of the ski and draping down into the little tray you created or just rely on the filled epoxy to hold the tray in place? Guess there is all that area on the sides of the tray to bond onto the filled section between the inner and outer layer of the ski so you probably don't need to.

And of course the big question, how well does it drain compared to the standard Venturi ?

Did you put a layer of glass lapping over the inside face of the ski and draping down into the little tray you created or just rely on the filled epoxy to hold the tray in place? Guess there is all that area on the sides of the tray to bond onto the filled section between the inner and outer layer of the ski so you probably don't need to.

And of course the big question, how well does it drain compared to the standard Venturi ?

Please Log in or Create an account to join the conversation.

- Simon Haywood

-

Topic Author

Topic Author

- Offline

- Elite Member

Less

More

- Posts: 186

- Thank you received: 70

10 years 6 months ago #22016

by Simon Haywood

Previous craft: Affinity, Endorfinn, Multisport, Epic V8, V10sport, V10, V12, Fenn Swordfish, Spirit PRS Elite; Stellar S18S, SR, SE, SEL, S2E, S2EL

Current Skis:

Huki S1-R

Stellar S18S - Excel

Stellar SR - Ultra

Skis on order: None!

Replied by Simon Haywood on topic Venturi-ectomy – Bailer-plasty

Jonathan, The tray has a layer of chop strand on the exterior - so is quite rough(grippy). The mix I use for bonding the tray to the ski has strands of carbon fibre & glass suspended in the mix. There is a fair bit of surface area in this bonding process...I purposely didn't post this procedure for a year to make sure there are no problems.

The Andersen bailer in my opinion is between 50%-100% better than the orignal system (i see they are now putting double venturi in most models - twice the drag 100% of the time)...mine is fully adjustable on the fly...When its up there is virtually no drag. When you are sitting on the start line your ski is filling up - I have the bailer up (getting just a little bit of seepage)

Anyone noticed catching a strand of weed how much that slows the ski - I can only imagine what the venturi/bullet hood does to the glide of the ski. I've also noticed on some skis a raised box section around their bailers on the exterior - surely that could be better finished off at the factory...on some it's quite the lip.

The Andersen bailer in my opinion is between 50%-100% better than the orignal system (i see they are now putting double venturi in most models - twice the drag 100% of the time)...mine is fully adjustable on the fly...When its up there is virtually no drag. When you are sitting on the start line your ski is filling up - I have the bailer up (getting just a little bit of seepage)

Anyone noticed catching a strand of weed how much that slows the ski - I can only imagine what the venturi/bullet hood does to the glide of the ski. I've also noticed on some skis a raised box section around their bailers on the exterior - surely that could be better finished off at the factory...on some it's quite the lip.

Previous craft: Affinity, Endorfinn, Multisport, Epic V8, V10sport, V10, V12, Fenn Swordfish, Spirit PRS Elite; Stellar S18S, SR, SE, SEL, S2E, S2EL

Current Skis:

Huki S1-R

Stellar S18S - Excel

Stellar SR - Ultra

Skis on order: None!

Please Log in or Create an account to join the conversation.

10 years 5 months ago #22032

by Newbflat

FENN Bluefin S

FENN Swordfish S carbon hybrid

Epic V8 double gen 2

Lot and lots of DK rudders.

Had:

Stellar SEL excel (gen 2)

Stellar SR excel (gen2)

Stellar S18s g1 (excel)

Epic V10 Double (performance)

Stellar SR (gen 1)

V10 sport (gen 2)

V10 (Gen 2)

Beater SEL (gen 1)

Replied by Newbflat on topic Venturi-ectomy – Bailer-plasty

Thanks for posting this.. I was going to use Anderson's but called Epic and bought two of there bailers for $89 US each.. That's about half the price of the Anderson's and I think it's a bit better system. I have been very happy with mine for the last year and it functions the same as new. I do dry lube it ocationaly to keep it moving freely. It remains totaly dry when closed and a little water enters when open in the first possion, about a cup that doesn't really drain. But man, when it's all the way open and you move in at 10+ kph it will suck your foot out the bottom of the ski if your not carful. Not sure how different they are to mount but will adjust accordingly.

My Stellar SR and S18s will be very happy after the Bailerplasty

Thanks again..!

Bill

My Stellar SR and S18s will be very happy after the Bailerplasty

Thanks again..!

Bill

FENN Bluefin S

FENN Swordfish S carbon hybrid

Epic V8 double gen 2

Lot and lots of DK rudders.

Had:

Stellar SEL excel (gen 2)

Stellar SR excel (gen2)

Stellar S18s g1 (excel)

Epic V10 Double (performance)

Stellar SR (gen 1)

V10 sport (gen 2)

V10 (Gen 2)

Beater SEL (gen 1)

Please Log in or Create an account to join the conversation.

- Canadasurfskiguy

- Offline

- Junior Member

Less

More

- Posts: 24

- Thank you received: 1

8 years 2 months ago #27769

by Canadasurfskiguy

Replied by Canadasurfskiguy on topic Venturi-ectomy – Bailer-plasty

Hi,

I recently got a 1st gen SES, I really like the hull but need to address of function issues one of which is the very poor bailing. I just bought an epic bailer thinking that I'd just figure out the install but fear that I'm over my head as several aspects of this (nicely done!) anderson install don't make sense to me. I'm wondering if you have any pics of your epic bailer install? &/or would you entertain me asking a few questions about the process?

thanks

I recently got a 1st gen SES, I really like the hull but need to address of function issues one of which is the very poor bailing. I just bought an epic bailer thinking that I'd just figure out the install but fear that I'm over my head as several aspects of this (nicely done!) anderson install don't make sense to me. I'm wondering if you have any pics of your epic bailer install? &/or would you entertain me asking a few questions about the process?

thanks

Please Log in or Create an account to join the conversation.

- Simon Haywood

-

Topic Author

Topic Author

- Offline

- Elite Member

Less

More

- Posts: 186

- Thank you received: 70

8 years 2 months ago #27771

by Simon Haywood

Previous craft: Affinity, Endorfinn, Multisport, Epic V8, V10sport, V10, V12, Fenn Swordfish, Spirit PRS Elite; Stellar S18S, SR, SE, SEL, S2E, S2EL

Current Skis:

Huki S1-R

Stellar S18S - Excel

Stellar SR - Ultra

Skis on order: None!

Replied by Simon Haywood on topic Venturi-ectomy – Bailer-plasty

Ian,

Are you wanting information on installation? If so can you articulate your problem/concern? Although, I've never fitted an Epic bailer can't really see they would be much different to an Andersen installation.

Are you wanting information on installation? If so can you articulate your problem/concern? Although, I've never fitted an Epic bailer can't really see they would be much different to an Andersen installation.

Previous craft: Affinity, Endorfinn, Multisport, Epic V8, V10sport, V10, V12, Fenn Swordfish, Spirit PRS Elite; Stellar S18S, SR, SE, SEL, S2E, S2EL

Current Skis:

Huki S1-R

Stellar S18S - Excel

Stellar SR - Ultra

Skis on order: None!

Please Log in or Create an account to join the conversation.

- Canadasurfskiguy

- Offline

- Junior Member

Less

More

- Posts: 24

- Thank you received: 1

8 years 2 months ago #27774

by Canadasurfskiguy

Replied by Canadasurfskiguy on topic Venturi-ectomy – Bailer-plasty

I just wrote a big reply but it said my session timed out... rats.

That would be super helpful if I could pick your brain a little bit. Thanks Simon.

How is the mold used? It is made from/using the dimension of, the bailer?

Does the anderson bailer have a metal backing piece that the bailer bolts on to? Do I have to use bolts with the epic bailer (there are 6 holes around the perimeter, but there's not backing plate so I don't know what I would bolt it to)?

I'll describe a process that makes sense to me and maybe you could point out flaws (possibly the whole plan...). There are two layers of boat, the footwell and the hull. I would cute a rectangle out of the footwell that would let the whole bailer pass through and sit on the inside of the hull. I would cut a smaller rectangle out of the hull that would alllow the moving bailer piece to pass through to the underside of the hull.

Next, one would need to adjust the height so that the bailer piece is flush with the outside of the hull. There are two rudder gasket like things that sit on the main body of the bailer, around the centre moving piece. They can be removed and would cause the moving bailer piece to sit lower. I don't know if I can glass onto either the rubber or the bare plastic or which is a better boding surface.

Once, the bailer is sitting on the inside of the hull and is flush with the outside, then I would try to glass everthing into place. I don't have a detailed plan for this but I imagine the most challening aspect would be filling the gap between the bailer and the footwell.

What do you think? Am I way out to lunch?

That would be super helpful if I could pick your brain a little bit. Thanks Simon.

How is the mold used? It is made from/using the dimension of, the bailer?

Does the anderson bailer have a metal backing piece that the bailer bolts on to? Do I have to use bolts with the epic bailer (there are 6 holes around the perimeter, but there's not backing plate so I don't know what I would bolt it to)?

I'll describe a process that makes sense to me and maybe you could point out flaws (possibly the whole plan...). There are two layers of boat, the footwell and the hull. I would cute a rectangle out of the footwell that would let the whole bailer pass through and sit on the inside of the hull. I would cut a smaller rectangle out of the hull that would alllow the moving bailer piece to pass through to the underside of the hull.

Next, one would need to adjust the height so that the bailer piece is flush with the outside of the hull. There are two rudder gasket like things that sit on the main body of the bailer, around the centre moving piece. They can be removed and would cause the moving bailer piece to sit lower. I don't know if I can glass onto either the rubber or the bare plastic or which is a better boding surface.

Once, the bailer is sitting on the inside of the hull and is flush with the outside, then I would try to glass everthing into place. I don't have a detailed plan for this but I imagine the most challening aspect would be filling the gap between the bailer and the footwell.

What do you think? Am I way out to lunch?

Please Log in or Create an account to join the conversation.

- Uffilation

-

- Offline

- Platinum Member

- ... trying not to mistake a mirror for a window

Less

More

- Posts: 348

- Thank you received: 70

8 years 2 months ago - 8 years 2 months ago #27777

by Uffilation

Replied by Uffilation on topic Venturi-ectomy – Bailer-plasty

great "How to" thread for retrofitting ...

when it comes to easy heel operation and efficiency, the DeBrito bailer is an option, too, imo ... which is why I'll replace my Anderson sooner or later with one

when it comes to easy heel operation and efficiency, the DeBrito bailer is an option, too, imo ... which is why I'll replace my Anderson sooner or later with one

Last edit: 8 years 2 months ago by Uffilation.

Please Log in or Create an account to join the conversation.

- Simon Haywood

-

Topic Author

Topic Author

- Offline

- Elite Member

Less

More

- Posts: 186

- Thank you received: 70

8 years 2 months ago - 8 years 2 months ago #27779

by Simon Haywood

Previous craft: Affinity, Endorfinn, Multisport, Epic V8, V10sport, V10, V12, Fenn Swordfish, Spirit PRS Elite; Stellar S18S, SR, SE, SEL, S2E, S2EL

Current Skis:

Huki S1-R

Stellar S18S - Excel

Stellar SR - Ultra

Skis on order: None!

Replied by Simon Haywood on topic Venturi-ectomy – Bailer-plasty

Ian,

Please note: I’m not a boat builder – just someone that likes to muck about with things that float!

The skis of mine that I’ve done with Andersen Bailers: – Stellar SE – Excel, SEL – Ultra, SEI – Excel and Ultra, SR – Excel (Gen1) and 2 x SR-Ultra(Gen2). I don’t work on other peoples skis…So take that into consideration – I’m only giving you an opinion FWIW.

(I’ve owned a total of 14 x Stellar Skis, 5 x Epic’s, A Fenn Swordfish and a Huki S1R)

I did the first one on Stellar SE Excel pretty much as per your thoughts – It was done ‘freestyle’ (no mould) bolts were mounted exterior and then camouflaged – A lot of work to make it look right!

Q. How is the mold used? – A. a mould saves time in fitting and gives a superior finish.

Q. Is it made from using the dimension of the bailer? – A. Yes – make it to suit the dimensions of your bailer - An Andersen Bailer is 7.8mm mounting clearance.

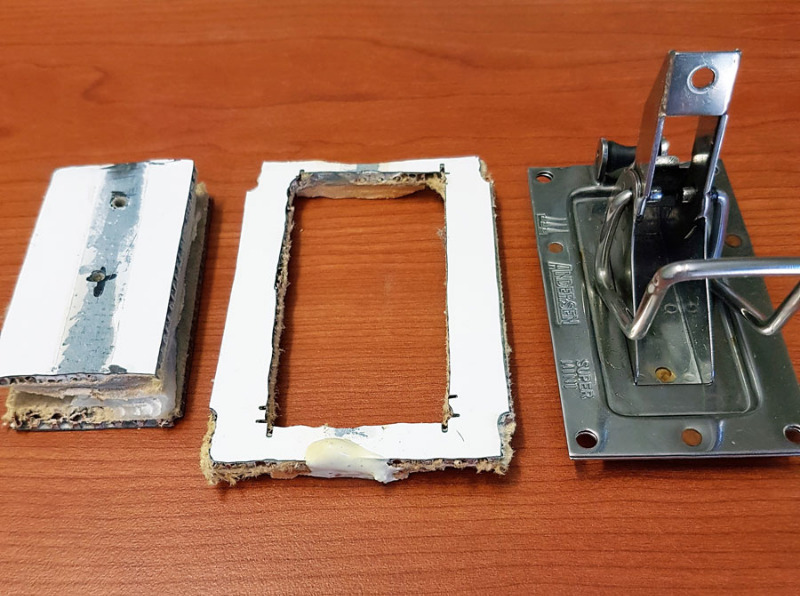

My home made mould and Andersen Super Mini 'Special' bailer.

L-R cut out of cockpit & exterior, the cut out of cockpit, Andersen Bailer (super mini 'Special') - needs the upstand to activate with tennis ball - for a one movement open & close.

Q. Does the Andersen bailer have a metal backing piece that the bailer bolts on to? A. Some do - The Andersen Bailer I use is the Super Mini ‘Special’ it does not have a metal backing plate. The bolts mount from the interior – we mount the bolts to the exterior of tray (created from mould) which when mounted in the ski disappears in the bonding process leaving only the threads sticking up into the interior/cockpit of the ski (visible).

NB: The bolts need to be notched and fibreglassed in so the do not turn when doing up the nut when fixing it in.

This is what the finished product looks like - before fitting the bailer. It's a good idea to be able to remove bailer for sevicing and replacement.

exterior view fitted

Please note: I’m not a boat builder – just someone that likes to muck about with things that float!

The skis of mine that I’ve done with Andersen Bailers: – Stellar SE – Excel, SEL – Ultra, SEI – Excel and Ultra, SR – Excel (Gen1) and 2 x SR-Ultra(Gen2). I don’t work on other peoples skis…So take that into consideration – I’m only giving you an opinion FWIW.

(I’ve owned a total of 14 x Stellar Skis, 5 x Epic’s, A Fenn Swordfish and a Huki S1R)

I did the first one on Stellar SE Excel pretty much as per your thoughts – It was done ‘freestyle’ (no mould) bolts were mounted exterior and then camouflaged – A lot of work to make it look right!

Q. How is the mold used? – A. a mould saves time in fitting and gives a superior finish.

Q. Is it made from using the dimension of the bailer? – A. Yes – make it to suit the dimensions of your bailer - An Andersen Bailer is 7.8mm mounting clearance.

My home made mould and Andersen Super Mini 'Special' bailer.

L-R cut out of cockpit & exterior, the cut out of cockpit, Andersen Bailer (super mini 'Special') - needs the upstand to activate with tennis ball - for a one movement open & close.

Q. Does the Andersen bailer have a metal backing piece that the bailer bolts on to? A. Some do - The Andersen Bailer I use is the Super Mini ‘Special’ it does not have a metal backing plate. The bolts mount from the interior – we mount the bolts to the exterior of tray (created from mould) which when mounted in the ski disappears in the bonding process leaving only the threads sticking up into the interior/cockpit of the ski (visible).

NB: The bolts need to be notched and fibreglassed in so the do not turn when doing up the nut when fixing it in.

This is what the finished product looks like - before fitting the bailer. It's a good idea to be able to remove bailer for sevicing and replacement.

exterior view fitted

Previous craft: Affinity, Endorfinn, Multisport, Epic V8, V10sport, V10, V12, Fenn Swordfish, Spirit PRS Elite; Stellar S18S, SR, SE, SEL, S2E, S2EL

Current Skis:

Huki S1-R

Stellar S18S - Excel

Stellar SR - Ultra

Skis on order: None!

Last edit: 8 years 2 months ago by Simon Haywood.

The following user(s) said Thank You: CB23

Please Log in or Create an account to join the conversation.

8 years 2 months ago #27851

by Cryder

Replied by Cryder on topic Venturi-ectomy – Bailer-plasty

There is a new bailer option that I believe fits the standard Anderson / Epic bolt patterns: debrito.se/

Pretty sure these are on the Nelo, NK and Think skis.

Pretty sure these are on the Nelo, NK and Think skis.

Please Log in or Create an account to join the conversation.

- Uffilation

-

- Offline

- Platinum Member

- ... trying not to mistake a mirror for a window

Less

More

- Posts: 348

- Thank you received: 70

8 years 2 months ago #27881

by Uffilation

Replied by Uffilation on topic Venturi-ectomy – Bailer-plasty

Cryder,

the debrito is more efficient and easier to heel operate (two mechanism optionable usable) IMO,

and fits the Epic/Anderson cut-out. I'll replace both the Andersen and Epic on my two skis this winter.

www.surfski.info/forum/15-tips/18192-ven...er-plasty.html#27777

the debrito is more efficient and easier to heel operate (two mechanism optionable usable) IMO,

and fits the Epic/Anderson cut-out. I'll replace both the Andersen and Epic on my two skis this winter.

www.surfski.info/forum/15-tips/18192-ven...er-plasty.html#27777

Please Log in or Create an account to join the conversation.

Latest Forum Topics

-

- Paddling with rotator cuff injury

- 34 minutes ago

-

- McGregor Rhythm questions

- 3 days 2 hours ago