- Posts: 2

- Thank you received: 1

Which “should” be faster?

5 years 8 months ago - 5 years 8 months ago #34696

by sunparrot

Which “should” be faster? was created by sunparrot

I’m paddling my Epic V8 Pro in a short race for fun on Intercoastal waters (so no surf) in a few days, and I have a banged up rudder on it with no way to buy and get a new rudder to me in time for the race.

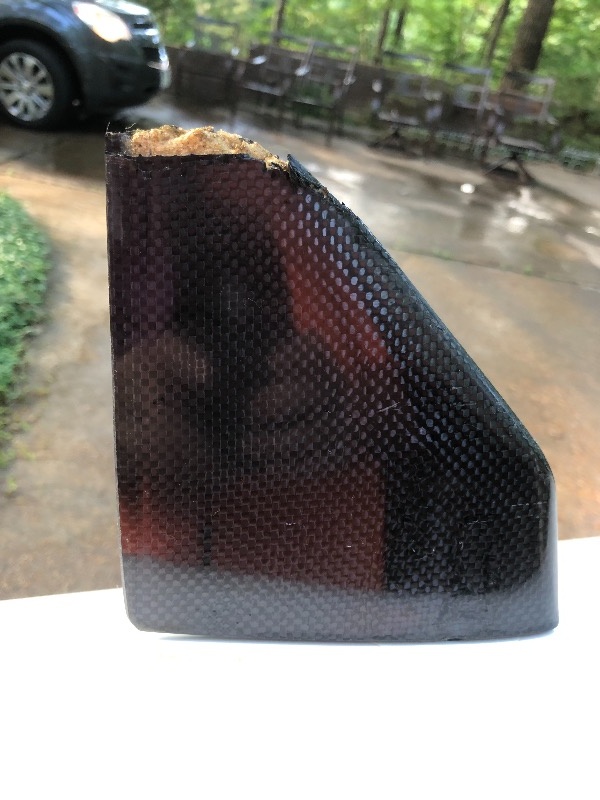

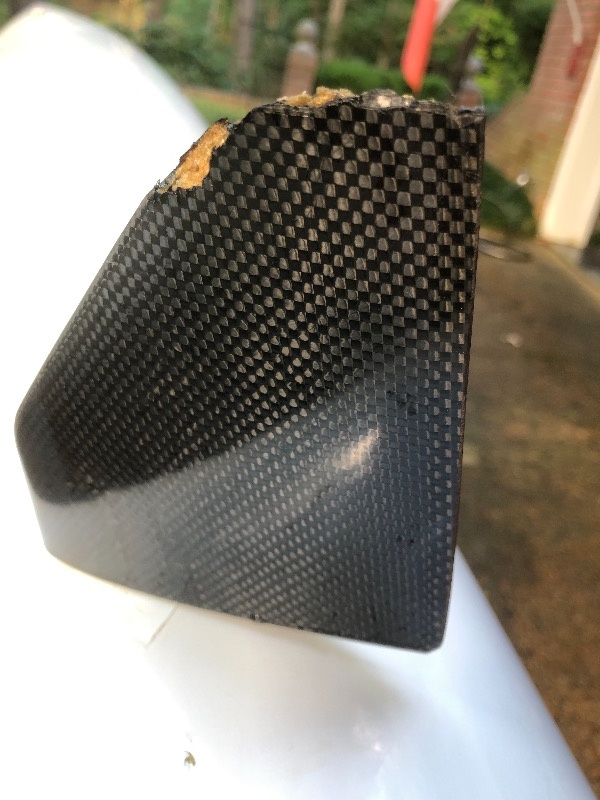

My damaged rudder is 5” L x 4-7/8” W - photos attached. I have a new 6” L x 5” W rudder on hand. Which do you think would allow me the greatest speed? Should I stick with the shorter 5” rudder, even though it’s banged up, or go with the smoother but longer 6” rudder?

If the 6” rudder would slow me down, would it slow me down a lot or just a negligible amount? Female paddler. Interested in your opinions and experience. Thanks!

My damaged rudder is 5” L x 4-7/8” W - photos attached. I have a new 6” L x 5” W rudder on hand. Which do you think would allow me the greatest speed? Should I stick with the shorter 5” rudder, even though it’s banged up, or go with the smoother but longer 6” rudder?

If the 6” rudder would slow me down, would it slow me down a lot or just a negligible amount? Female paddler. Interested in your opinions and experience. Thanks!

Last edit: 5 years 8 months ago by [email protected]. Reason: Embedded the images in the body of the message.

Please Log in or Create an account to join the conversation.

- [email protected]

-

- Offline

- Admin

Less

More

- Posts: 1839

- Thank you received: 411

5 years 8 months ago #34699

by [email protected]

Rob

Currently Epic V10 Elite, Epic V10 Double.

Previously: Swordfish S, Evo II, Carbonology Zest, Fenn Swordfish, Epic V10, Fenn Elite, Red7 Surf70 Pro, Epic V10 Sport, Genius Blu, Kayak Centre Zeplin, Fenn Mako6, Custom Kayaks ICON, Brian's Kayaks Molokai, Brian's Kayaks Wedge and several others...

Replied by [email protected] on topic Which “should” be faster?

Thoughts:

- I think the extra inch would have negligible effect in terms of drag... in reality. However, never underestimate the effect on your brain. If you have a nagging thought that you have a draggy rudder, you'll probably enjoy the race less!!! I know that has happened to me before and I've spent the race kicking myself for not using a smaller, "less draggy" rudder! This is particularly relevant if there's a possibility that there will be weed on the course.

- You could make a running repair on that rudder by putting some good quality duct tape carefully over the broken edges, to smooth them off. Good duct tape should last a race without coming off. You could also simply repair the rudder with some body filler, sanding it off to a good shape - if the race is in a few days, you definitely have time to do that. If you do a good enough job, you could keep the rudder as a spare when you replace it.

Rob

Currently Epic V10 Elite, Epic V10 Double.

Previously: Swordfish S, Evo II, Carbonology Zest, Fenn Swordfish, Epic V10, Fenn Elite, Red7 Surf70 Pro, Epic V10 Sport, Genius Blu, Kayak Centre Zeplin, Fenn Mako6, Custom Kayaks ICON, Brian's Kayaks Molokai, Brian's Kayaks Wedge and several others...

The following user(s) said Thank You: sunparrot

Please Log in or Create an account to join the conversation.

5 years 8 months ago #34704

by mrcharly

Replied by mrcharly on topic Which “should” be faster?

I would go for the repair, myself.

Some body filler is hydroscopic, so maybe check that or use filler and add some plain epoxy on top after you have smoothed it.

Some body filler is hydroscopic, so maybe check that or use filler and add some plain epoxy on top after you have smoothed it.

The following user(s) said Thank You: sunparrot

Please Log in or Create an account to join the conversation.

- ccchappell

-

- Offline

- Senior Member

Less

More

- Posts: 66

- Thank you received: 25

5 years 8 months ago #34706

by ccchappell

Replied by ccchappell on topic Which “should” be faster?

I have good luck with an epoxy stick, actually use for permanent repairs fast. Once cures, shape with a file/rasp and some sand paper. 100% waterproof... A bit expensive but works well

www.westmarine.com/buy/west-marine--epoxy-putty-stick--3761483

www.westmarine.com/buy/west-marine--epoxy-putty-stick--3761483

The following user(s) said Thank You: sunparrot

Please Log in or Create an account to join the conversation.

5 years 8 months ago #34707

by Fath2o

Replied by Fath2o on topic Which “should” be faster?

Body filler or "Bondo" would work fine and is much easier to sand, but is only a temporary repair. The epoxy stick would be easier to apply because it is thicker and won't run. The epoxy stick is much more difficult to sand. Do not over apply. The epoxy will last much longer.

Both products are available at big box home centers like Lowe's for a fraction of the cost at "Fleece Marine". Epoxy stick $5.98 @ Lowe's.

www.lowes.com/pd/Oatey-Fix-It-Stick-Epoxy-Putty/3132883

Both products are available at big box home centers like Lowe's for a fraction of the cost at "Fleece Marine". Epoxy stick $5.98 @ Lowe's.

www.lowes.com/pd/Oatey-Fix-It-Stick-Epoxy-Putty/3132883

The following user(s) said Thank You: sunparrot

Please Log in or Create an account to join the conversation.

5 years 8 months ago - 5 years 8 months ago #34708

by DougMar

Replied by DougMar on topic Which “should” be faster?

I've had to repair most every rudder I've had over a 12 year period with my V12. I usually use West Systems 2-part 105 epoxy with carbon powder additive for toughness and a good color match.

Early this spring I had a immediate boat-stopping close encounter with a submerged root or branch just days before a race. I was in a sprint going through some thin suck-water that popped me up to bow-wave-skip to a greater speed. The impact instantly stopped me from 10 mph to zero. Amazing I didn't fall out of the boat and that the rudder tube and hull showed no signs of stress or damage. A good testament to the strength of the Epic Ultra construction (G-1 V12). The leading edge of the rudder was crushed near the root of the rudder, very close to the hull, but the rudder shaft remained perfectly straight. Crazy. If I had hit more towards the rudder's tip, hull and/or shaft damage may have occurred.

I dried the structural foam by putting the rudder on the dashboard of my vehicle on the way home after the incident, then cleaned up the jagged edges with sandpaper and applied a couple coats of JB Weld epoxy (gray in color - available at most every hardware store as well as all the big-boxes) and waited for it to fully cure (12 hrs for the slow cure). Sanded it to shape and it looks perfect to the water flow, albeit appears like a repair. But it worked well for a few races until I was able to properly repair it with the fore-mentioned carbon-epoxy repair.

This same small rudder (the same as pictured by the OP) has been mutilated several times in the past 12 years, each time receiving a rebuild with very good results. Seems like a rudder always needs a repair just before a race.

This past repair I added a wedge-shape extension onto the root area of the rudder to make the rudder profile look like a truncated triangle, all faired in to provide a proper hydrodynamic foil section shape. This does a better job of allowing the rudder to glance over obstacles without damage, as well as keeping weed accumulation to absolutely nothing. Better than the Epic weed guard in front of the stock rudder.

When sanding the epoxy, use a heavy grit (80 to 100 grit) at first, and wrap it tightly against something like a stiff paint stick or such to provide a flat surface rather than merely taking a loose sheet of sandpaper to the rudder. Much easier to sculpt with. If it doesn't come out so well, just apply more epoxy and re-sculpt. As the form begins to closely resemble a proper foil shape, reduce the grit to 150, then 300, working up to 1200 or so grit for a silky-smooth finish. (I've gone up to 2500 grit and achieved a mirror-like finish) Most auto-parts stores, and all paint-supply stores carry the sandpaper grades you'll find most useful. Best bet is to use waterproof (wet) sandpaper dipped frequently in a bucket of water. Don't use the cheep sandpaper that is not waterproof, at least for the 150 grits and up. Don't worry about having to purchase the excess paper that comes in packs..... if you're at all like me and paddling a lot, you'll be needing it in the not-so-distant future with other repairs to the hull or rudders.

With all materials readily at hand, the repair takes me a realistic 15-20 minutes from start to race-ready, excluding epoxy curing time.

With a little elbow grease, you can repair your rudders to far better than stock condition. That also goes with hull damage.... but that process is a bit more involved.

Early this spring I had a immediate boat-stopping close encounter with a submerged root or branch just days before a race. I was in a sprint going through some thin suck-water that popped me up to bow-wave-skip to a greater speed. The impact instantly stopped me from 10 mph to zero. Amazing I didn't fall out of the boat and that the rudder tube and hull showed no signs of stress or damage. A good testament to the strength of the Epic Ultra construction (G-1 V12). The leading edge of the rudder was crushed near the root of the rudder, very close to the hull, but the rudder shaft remained perfectly straight. Crazy. If I had hit more towards the rudder's tip, hull and/or shaft damage may have occurred.

I dried the structural foam by putting the rudder on the dashboard of my vehicle on the way home after the incident, then cleaned up the jagged edges with sandpaper and applied a couple coats of JB Weld epoxy (gray in color - available at most every hardware store as well as all the big-boxes) and waited for it to fully cure (12 hrs for the slow cure). Sanded it to shape and it looks perfect to the water flow, albeit appears like a repair. But it worked well for a few races until I was able to properly repair it with the fore-mentioned carbon-epoxy repair.

This same small rudder (the same as pictured by the OP) has been mutilated several times in the past 12 years, each time receiving a rebuild with very good results. Seems like a rudder always needs a repair just before a race.

This past repair I added a wedge-shape extension onto the root area of the rudder to make the rudder profile look like a truncated triangle, all faired in to provide a proper hydrodynamic foil section shape. This does a better job of allowing the rudder to glance over obstacles without damage, as well as keeping weed accumulation to absolutely nothing. Better than the Epic weed guard in front of the stock rudder.

When sanding the epoxy, use a heavy grit (80 to 100 grit) at first, and wrap it tightly against something like a stiff paint stick or such to provide a flat surface rather than merely taking a loose sheet of sandpaper to the rudder. Much easier to sculpt with. If it doesn't come out so well, just apply more epoxy and re-sculpt. As the form begins to closely resemble a proper foil shape, reduce the grit to 150, then 300, working up to 1200 or so grit for a silky-smooth finish. (I've gone up to 2500 grit and achieved a mirror-like finish) Most auto-parts stores, and all paint-supply stores carry the sandpaper grades you'll find most useful. Best bet is to use waterproof (wet) sandpaper dipped frequently in a bucket of water. Don't use the cheep sandpaper that is not waterproof, at least for the 150 grits and up. Don't worry about having to purchase the excess paper that comes in packs..... if you're at all like me and paddling a lot, you'll be needing it in the not-so-distant future with other repairs to the hull or rudders.

With all materials readily at hand, the repair takes me a realistic 15-20 minutes from start to race-ready, excluding epoxy curing time.

With a little elbow grease, you can repair your rudders to far better than stock condition. That also goes with hull damage.... but that process is a bit more involved.

Last edit: 5 years 8 months ago by DougMar.

Please Log in or Create an account to join the conversation.

- Steve Hansen

- Offline

- Premium Member

Less

More

- Posts: 126

- Thank you received: 24

5 years 8 months ago #34709

by Steve Hansen

Replied by Steve Hansen on topic Which “should” be faster?

Go with the 6", one inch won't make any difference. If anything it will make you more stable.

The following user(s) said Thank You: sunparrot

Please Log in or Create an account to join the conversation.

5 years 8 months ago - 5 years 8 months ago #34710

by DougMar

Replied by DougMar on topic Which “should” be faster?

I'll respectfully disagree with Steve Hansen. In my experience, especially in a smoother water race, the extra wetted surface area of the large surf rudder does make a huge difference in drag, especially when one second can separate the first and third place finishers.

A V8 is super-stable anyway, so no need for the supposed extra stability of a deeper rudder. The only point in a flatter-water race that a bigger, deeper rudder may help is on tight turns. If the race had a lot of tight turns, then yes, a deeper rudder may provide an advantage if the paddler is not adept at keeping the boat heeled it's outside deck-edge during a turn, a skill most every sea-kayaker and river-kayaker knows well but many ski-paddlers have not learned or practiced.

Take a few moments to repair your small rudder.

Edit... I thought Steve was referring to a surf rudder.... He's likely correct, a 6" rudder is not going to matter too much, especially on a V8. But if running through some shallows, it's slightly more likely to snag something, and you will have slightly more drag, but likely not enough to make more than a couple seconds of time difference. Certainly better than using the un-repaired 5" rudder.

A V8 is super-stable anyway, so no need for the supposed extra stability of a deeper rudder. The only point in a flatter-water race that a bigger, deeper rudder may help is on tight turns. If the race had a lot of tight turns, then yes, a deeper rudder may provide an advantage if the paddler is not adept at keeping the boat heeled it's outside deck-edge during a turn, a skill most every sea-kayaker and river-kayaker knows well but many ski-paddlers have not learned or practiced.

Take a few moments to repair your small rudder.

Edit... I thought Steve was referring to a surf rudder.... He's likely correct, a 6" rudder is not going to matter too much, especially on a V8. But if running through some shallows, it's slightly more likely to snag something, and you will have slightly more drag, but likely not enough to make more than a couple seconds of time difference. Certainly better than using the un-repaired 5" rudder.

Last edit: 5 years 8 months ago by DougMar.

The following user(s) said Thank You: sunparrot

Please Log in or Create an account to join the conversation.

5 years 8 months ago #34735

by paddlepop

Replied by paddlepop on topic Which “should” be faster?

The following user(s) said Thank You: sunparrot

Please Log in or Create an account to join the conversation.

5 years 7 months ago #34780

by sunparrot

Replied by sunparrot on topic Which “should” be faster?

I wanted to thank everyone who responded to my cry for help! I sent my husband out to find me the putty and sandpaper, crossed my fingers, and I went to work. My first application of the putty and my sanding wasn't very good, so I added a second round of putty and then headed out of town to my race. I sanded the rudder there, and it came out beautifully! It tracked just right in the water, and it looked pretty good, too, if I do say so myself! I would've never had the confidence to even try this without you guys helping me out. What a great group! Thank you so much! BTW - I won 1st place in the open division for my race!

The following user(s) said Thank You: Hiro

Please Log in or Create an account to join the conversation.

5 years 7 months ago #34781

by paddlepop

Replied by paddlepop on topic Which “should” be faster?

congratulations on gaining a new skill and confidence level which you'll no doubt use a fair bit in the future. even after lots of practice it always takes at least two fill and sand attempts to get a fin tip right. excellent paddling too. pete

The following user(s) said Thank You: sunparrot

Please Log in or Create an account to join the conversation.

Latest Forum Topics

-

- McGregor Rhythm questions

- 13 hours 13 minutes ago

-

- Paddling with rotator cuff injury

- 3 days 21 hours ago

-

- Fenn Fenix Cuda First Impressions

- 6 days 4 hours ago